Capping Systems

Scroll down for more details.

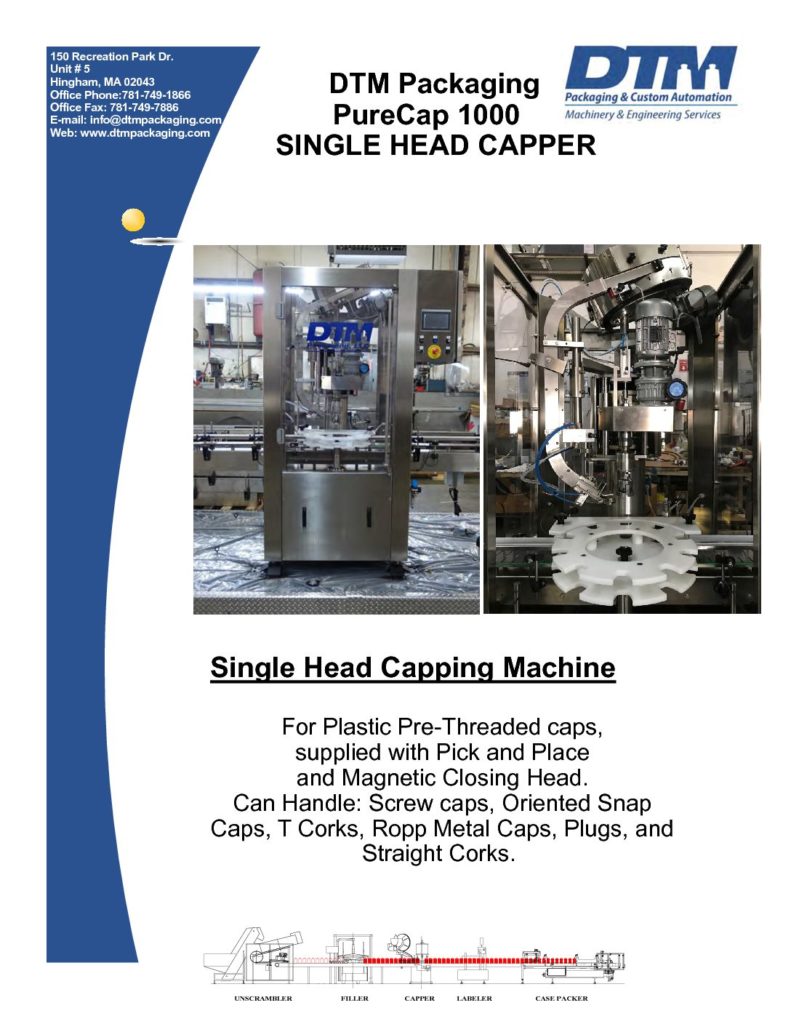

- Purecap 1000 Single Head Capper

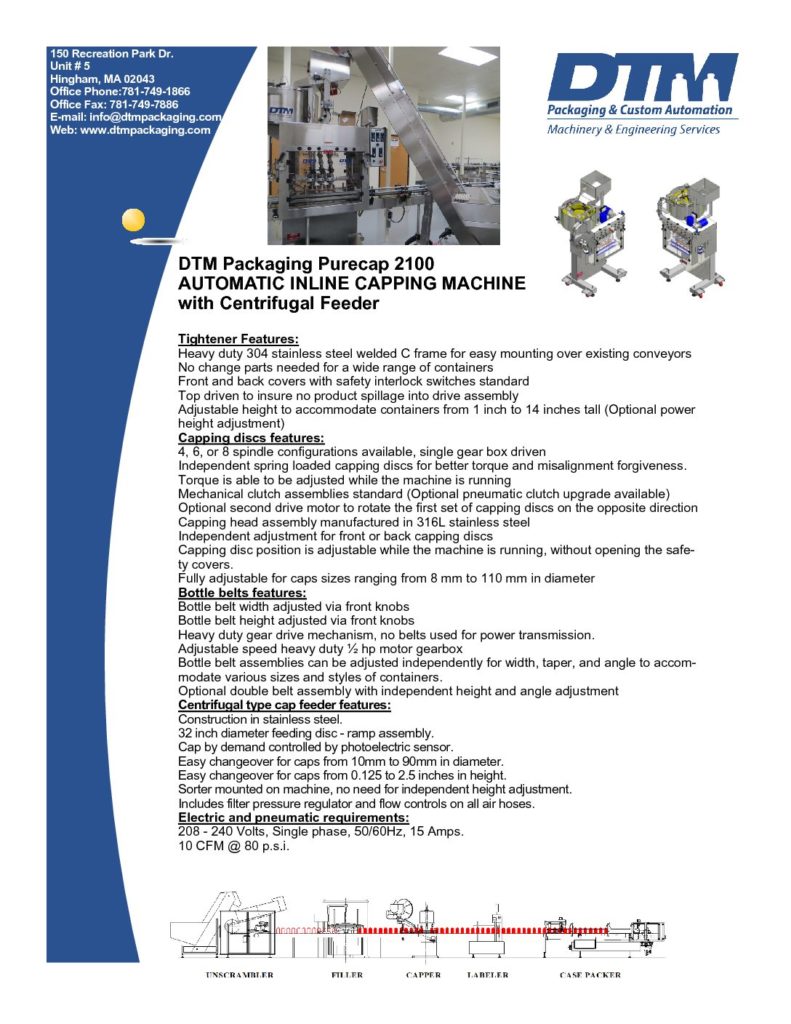

- Purecap 2100 In-Line Capper with Centrifugal Feeder

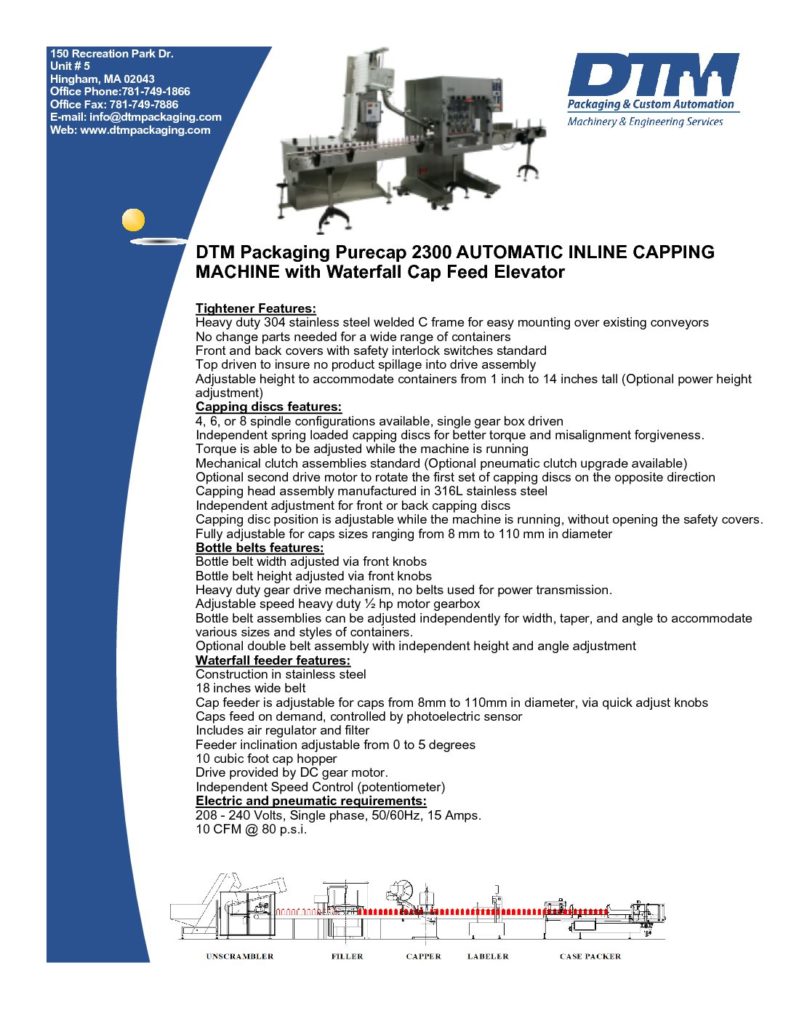

- Purecap 2300 In-Line Capper with Waterfall Feed System

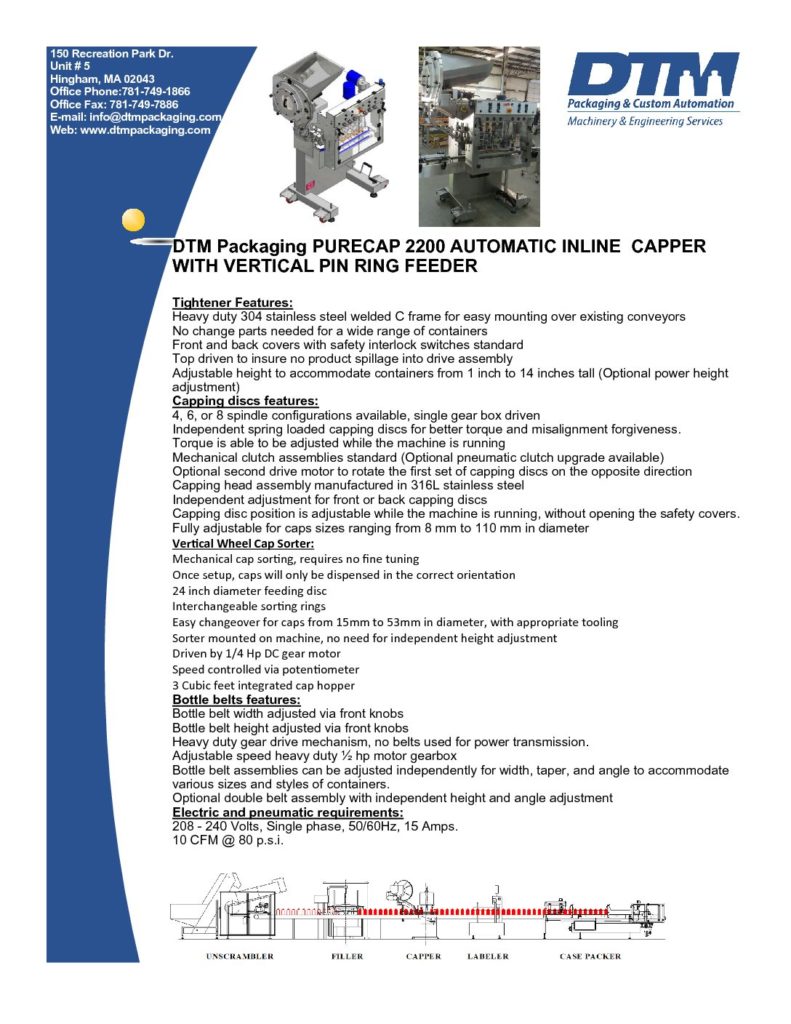

- Purecap 2200 In-Line Capper with Vertical Pin Ring Feeder

- Purecap 2000 Automatic In-Line Bottle Uncapper

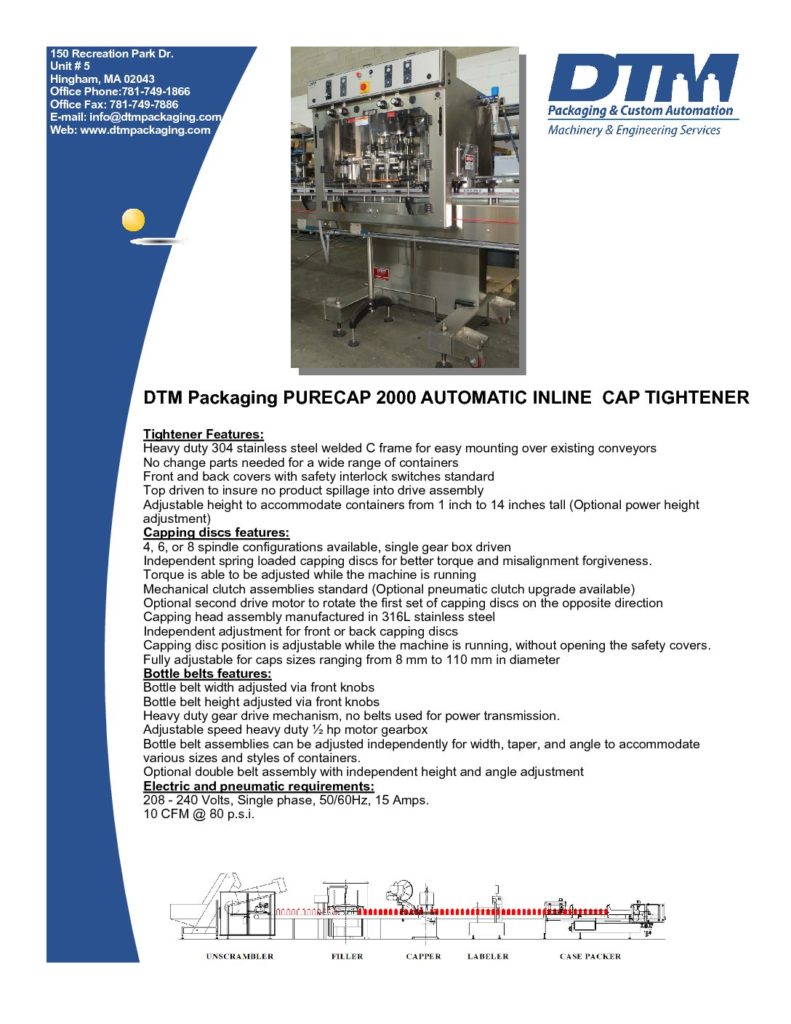

- Purecap 2000 Cap Tightener

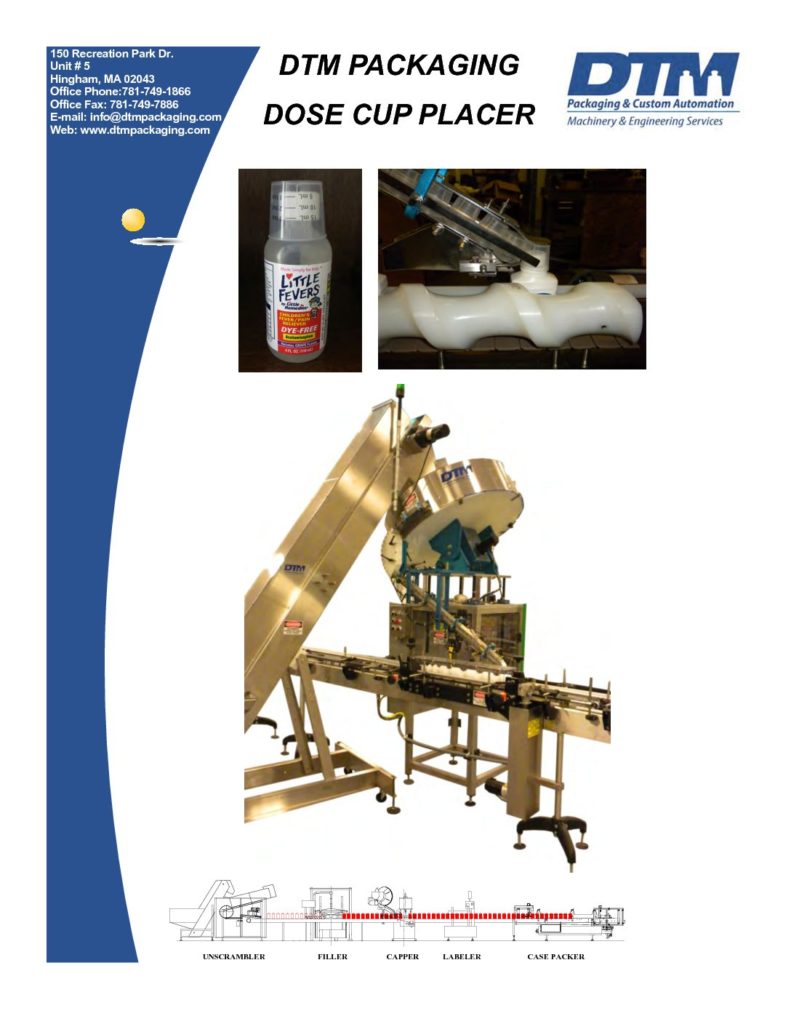

- Purecap Dose Cap Placer