New Machines

New Machines

Explore our Packaging Machines and Solutions. For more information, contact us today!

Capping Systems

Scroll down for more details.

- Purecap 1000 Single Head Capper

- Purecap 2100 In-Line Capper with Centrifugal Feeder

- Purecap 2300 In-Line Capper with Waterfall Feed System

- Purecap 2200 In-Line Capper with Vertical Pin Ring Feeder

- Purecap 2000 Automatic In-Line Bottle Uncapper

- Purecap 2000 Cap Tightener

- Purecap Dose Cap Placer

Remanufactured Bottle Stop and Spacing Wheels

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Bottle Pucking and Depucking Machinery

Inquire with our Sales department. Contact Us.

Packaging Guard Systems

- Cost-effectively brings existing machinery up to guarding safety standards, at a time that is convenient to you.

- Enhances the safety of your employees while improving the working environment.

- Quick installations minimize machine downtime and costly production interruptions.

- Barrier guards help avoid costly and time-consuming, product liability issues.

- Our designs modernize even the roughest looking equipment, helping to improve the appearance of your production area.

Scroll down for more details & to view our PDF.

Tooliong and Replacement Parts for Cap Feeders

Upgrades and Refurbished Product Lines

Scroll down for more details & to view our PDF.

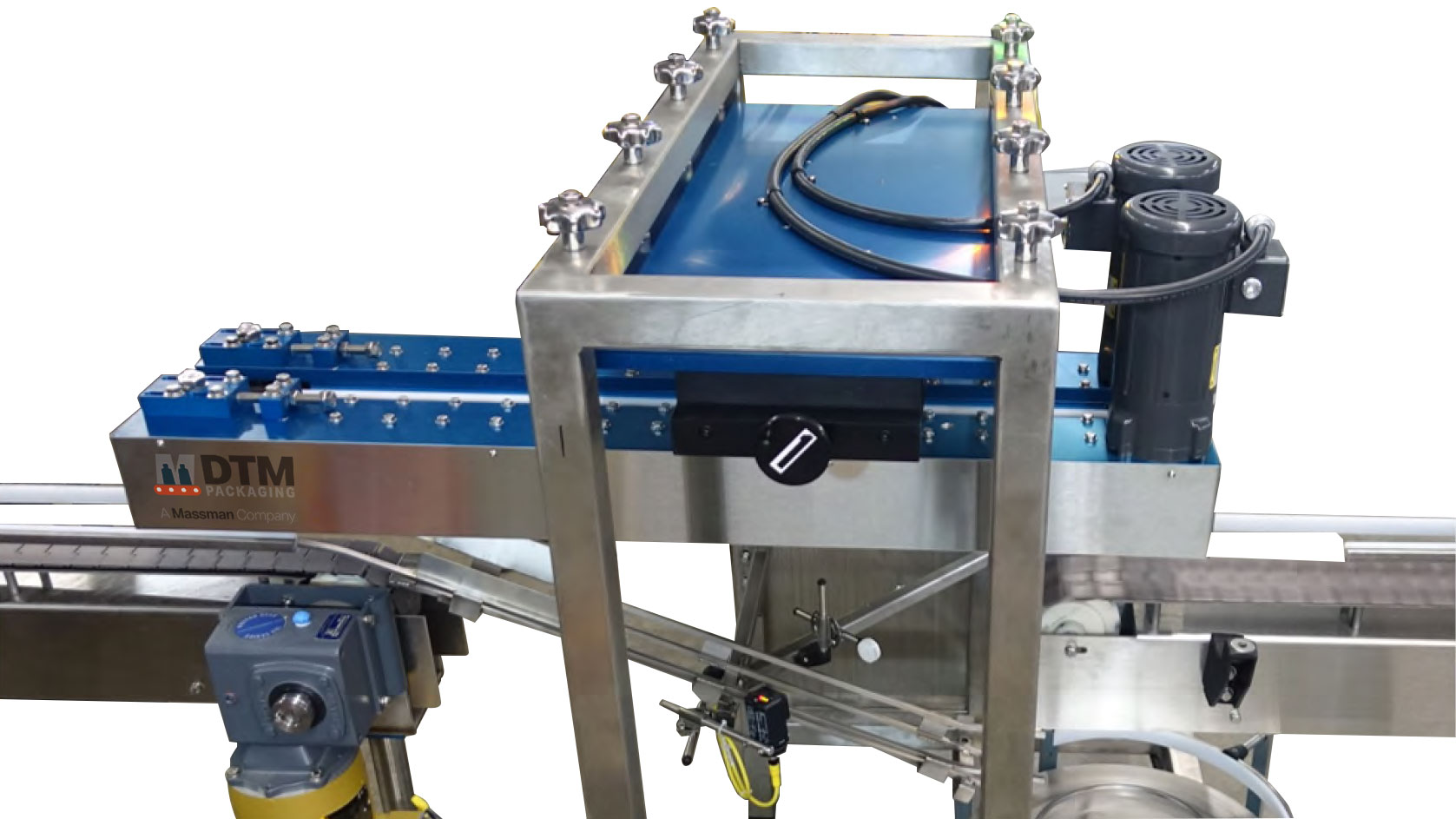

Diverter for Bottom Coding

Scroll down for more details & to view our PDF.

- Diverter for Bottom Coding and Depucking

- Diverter for Bottom Coding

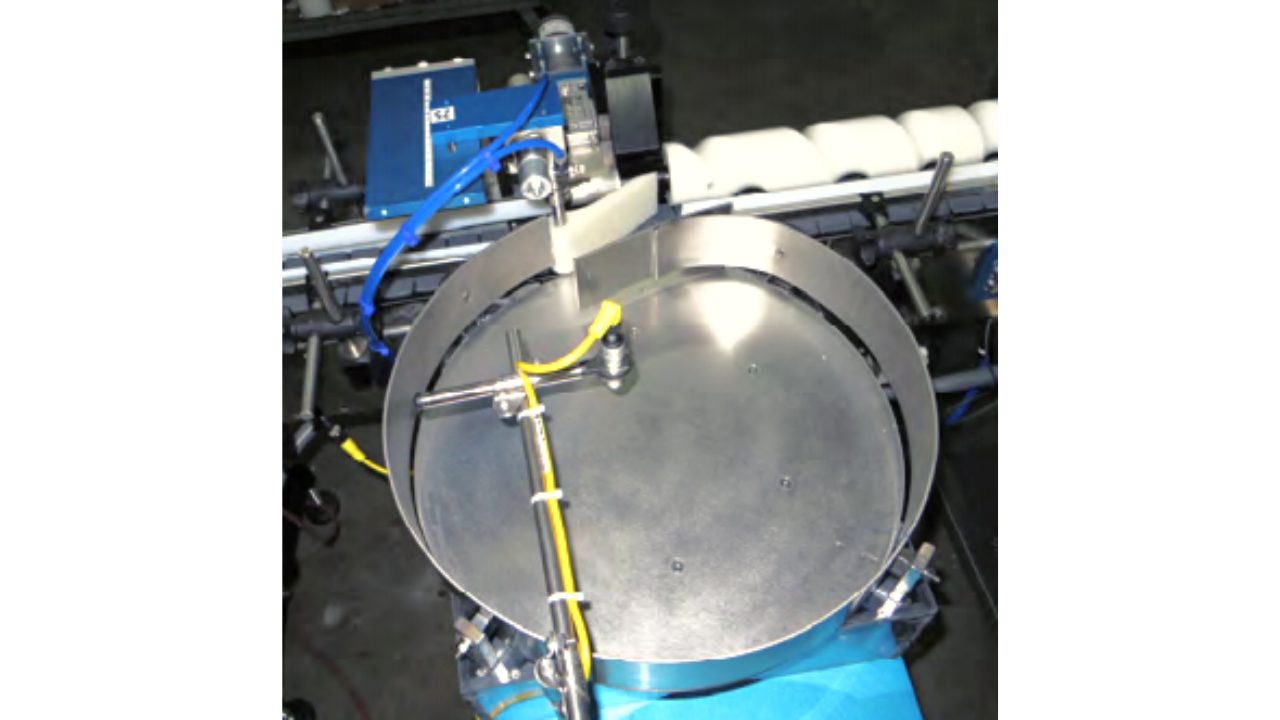

Remanufactured Rotary Tables

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Rotary Reject Tables

- Tables manufactured in 1/8” thick 304 stainless steel.

- Support of stainless steel disc by ½ inch aluminum plate.

- Main structure manufactured with 2 inch stainless steel square tubing.

- Power provided by DC gear motor.

- Speed control by potentiometer.

- Variable speed

Rotary Accumulation and Feed Tables

- Manufactured in 1/8” thick 304 stainless steel.

- Support of stainless steel disc by ½ inch aluminum plate.

- Main structure manufactured in 2 inch stainless steel square tube.

- Includes stainless steel covers on 4 sides.

- Power provided by DC gear motor.

- Speed control by potentiometer.

- Variable speed up to 150 containers per minute.

Scroll down for more details & to view our PDF.

Dose Cup Placer Machine

At DTM, we specialize in manufacturing and remanufacturing high-quality, high-speed Dose Cup Placers tailored to meet the diverse needs of our customers’ packaging machines. Our focus on precision engineering ensures that each unit is designed to enhance efficiency and reliability, significantly boosting the productivity of packaging lines. Whether you require a brand new system or need to upgrade an existing setup, our remanufactured Dose Cup Placers are meticulously restored to meet original specifications, offering a cost-effective and sustainable solution.

Pressurized Fluid and Supply Tanks

Pressurized fluid supply system with level control and flow control valve to meter liquid into the head tank on demand from the level control.

Scroll down for more details & to view our PDF.

Linear Pack Off System Tables

Overall Length – 6’-8’-10’ OR 12′ long on one side of conveyor with upper shelf for staging lay flat cases and lower shelf for manual packing.

Scroll down for more details & to view our PDF.

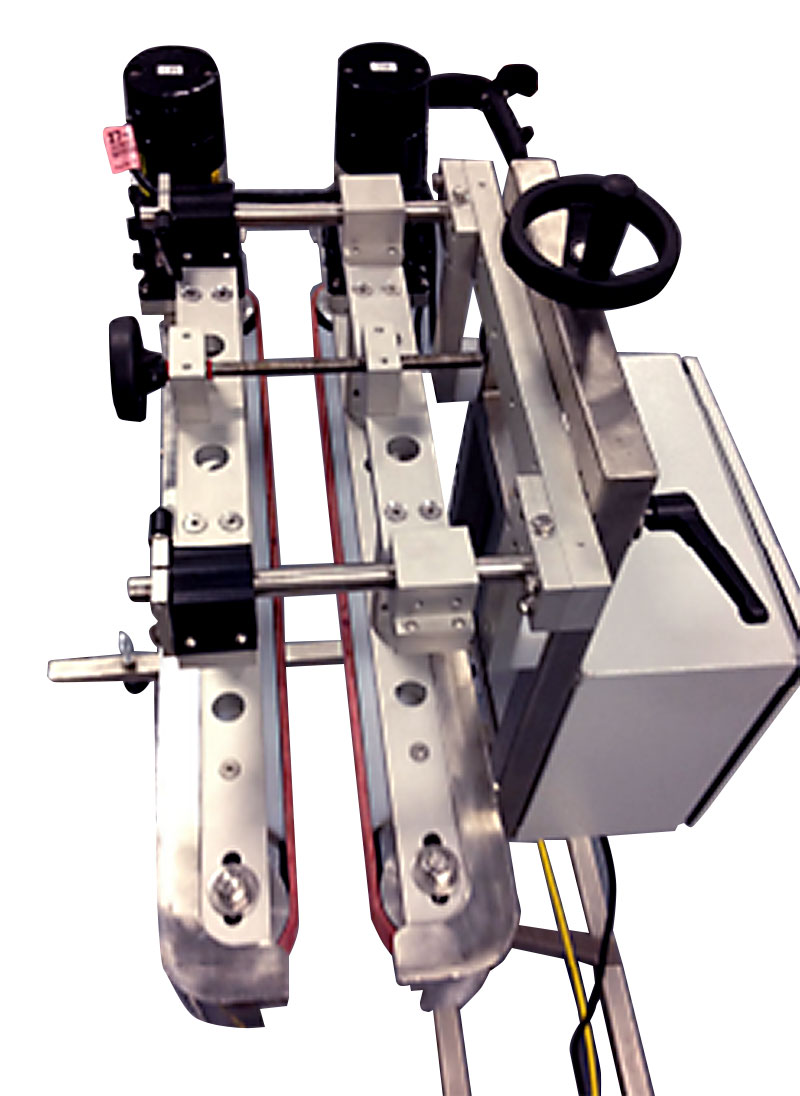

Dual Belt Depucking Machinery

- Stainless Steel frame construction

- Adjustments for different sizes of containers

take only minutes, without the need for change parts. - Dual driven two inch wide belts—easily adjustable

- Allen Bradley electrics

- Back up photo-eye

- OPTIONAL: Discharge chute with gradual puck decent and turn at end to

discharge onto 12″ rotary table to transport pucks from discharge chute onto

puck return conveyor.

Scroll down for more details & to view our PDF.

Conveyor Systems for Bottles and Cases

- Rugged Construction

- Modular Design

- Stainless Steel Construction

- Engineered For The Application

Scroll down for more details & to view our PDF.

Flip Cap Orientation System

STM Packaging’s Flip Cap Orientation System is designed to mechanically orient a hinge-style cap within the cap. This machine will guarantee your cap is oriented in the proper way to be placed on your bottle.

Cap orientation plays a huge role in the effectiveness of your packaging solutions. If a cap is not oriented properly it can cause delays and errors in the packaging line.

Scroll down for more details & to view our PDF.

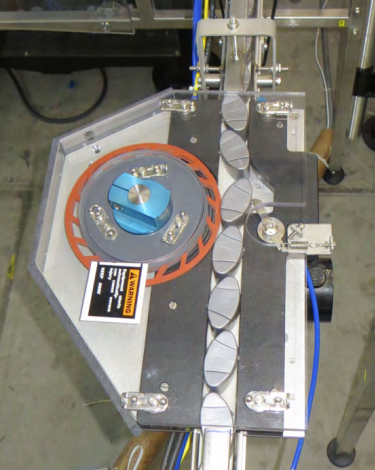

Centrifugal Cap Feeder

The centrifugal cap feeder was specifically designed to be extremely flexibility and capable of sorting and feeding a wide range of cap shapes and sizes including irregular shapes. This gentle control in handling is ideally suited for handling delicate finishes.

With quick-change interchangeable center sections, the feeder can be changed over in a matter of minutes. The cap feeder will play a significant role in the efficiency of your packaging line.

Click into ‘Resources’ to view our PDF.

Bottle Stop and Bottle Spacing Wheel

Scroll down for more details & to view our PDF.